Overview

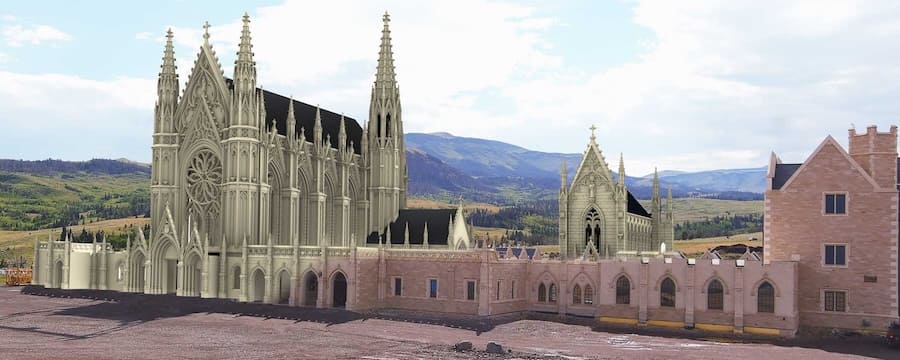

Nestled in the remote wilderness, the Carmelite Monks are not only dedicated to a life of prayer but also to a tradition of innovation and self-sufficiency. With a commitment to building a Gothic monastery from intricately carved stone, they have leveraged cutting-edge CNC technology to make their vision a reality. However, with the complexity of their machining operations, they needed a solution that could enhance precision and prevent costly errors—leading them to Eureka.

- Revolution of CNC machining workflow

- Identify and prevent potential crashes

- Verify toolpaths and optimize machining sequences

- Visualize the machining process

Challenges

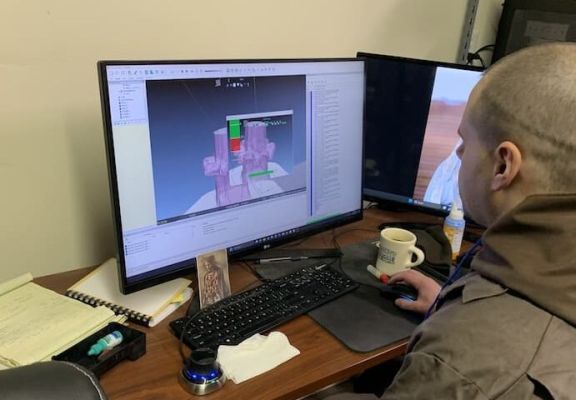

The monks faced significant challenges in their journey to mastering CNC machining. Their stonework involves large, intricate pieces with constant five-axis machining, creating a high potential for collisions and errors. Stonework is unforgiving—if cut incorrectly, the material can easily break, leading to costly mistakes. Additionally, the stone they use is very expensive and labor-intensive due to its incredible weight, requiring careful setup for machining. As self-taught machinists, they initially struggled with understanding G-code, post-processing errors, and verifying machining paths, all of which led to inefficiencies and material loss. They needed a reliable simulation tool that could bridge the gap between their CAM software and real-world execution.

The eureka Solution

Following thorough research, the Carmelites adopted Eureka’s G-code simulation software, revolutionizing their CNC machining workflow. By using Eureka, they were able to:

Chronos G-code Optimizer

Eureka Chronos is a CNC feedrate optimization software developed by Roboris Srl. Chronos optimizes G-code program feedrates using AI-based algorithms to maintain constant tool engagement and material removal while preserving the original CAM program’s toolpath geometry.

By implementing Chronos, the Carmelites achieved:

- Increased efficiency, gaining an additional 10-15% improvement in toolpath optimization.

- Reduced runtimes, saving hours per part in machining processes that typically span hours or even days.

- Enhanced machine longevity by maintaining consistent material removal rates and reducing tool wear.

- The ability to execute complex machining operations that were previously impossible to program properly in Mastercam.

Results

Integrating Eureka into their workflow has revolutionized the monastery’s CNC machining process, enabling greater precision and efficiency. The monks now operate with greater confidence, achieving precision in their stone carving while minimizing waste. Their collaboration with John, a dedicated Eureka expert, has further streamlined their processes, ensuring that their unique machining requirements are met with tailored solutions.

Customer Comment

Brother Isidore Mary, the primary Eureka User said, “The Chronos G-code optimizer has been a game changer as well. We’ve consistently seen that Chronos takes very good CAM-optimized toolpaths and gains another 10-15%. Our part runtimes are measured in hours and days, so even a 5% gain can equal an hour per part. This is huge! Since Chronos analyzes the material removal rate of the entire toolpath, it has also helped us to run faster while at the same time being easier on our machines. Once we define an ideal rate for the tool assembly, Chronos does the rest. For roughing out material, we frequently use wheels up to 4 feet in diameter, and the ability of Chronos to soften the plunge of a cutter that size to keep a consistent removal rate is impressive. This ability has even enabled us to run machinings that were impossible to program properly in Mastercam. All around, Chronos has been an incredible efficiency booster, consistently delivering superior results.”

...Chronos takes very good CAM-optimized toolpaths and gains another 10-15%. Our part runtimes are measured in hours and days, so even a 5% gain can equal an hour per part. This is huge!

A Unique Partnership

The story of the Carmelite Monks exemplifies the synergy between tradition and technology. While their monastic life is rooted in contemplation and prayer, their entrepreneurial spirit has driven them to embrace modern CNC innovations. With Eureka, they have successfully merged craftsmanship with digital precision, proving that even in the most unexpected places, technology can be a vital tool for progress.

Conclusion

The partnership between the Carmelite Monks and Eureka highlights the importance of adaptable solutions in CNC machining. By overcoming their initial challenges and leveraging advanced simulation software, the monks have not only refined their stone-carving process but have also set a precedent for how technology can serve even the most traditional of endeavors. Eureka has provided them with the confidence to pursue their ambitious architectural goals, ensuring that their vision of a Gothic monastery becomes a reality.